Understanding Bow Stranding Machine Factories: A Key to Efficient Wire Manufacturing

Release time:

2025-06-21

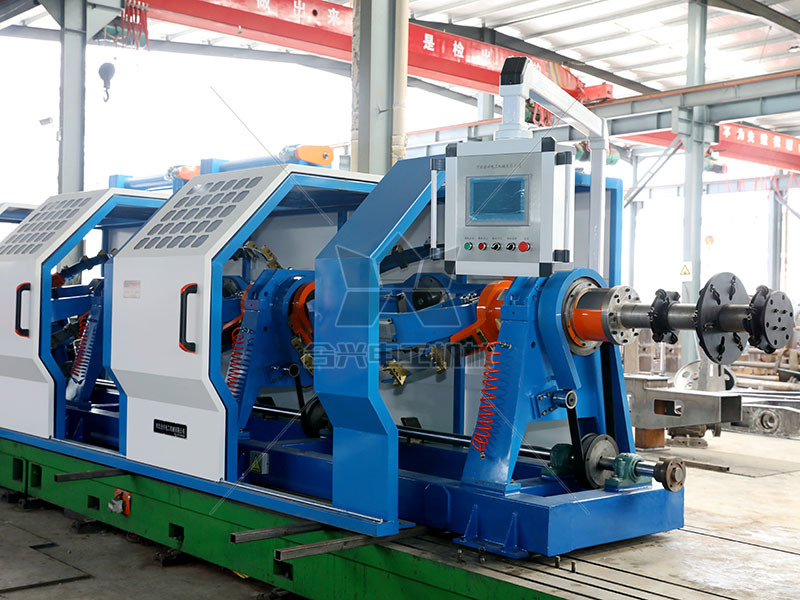

Bow stranding machines are essential in the manufacturing of electrical wires and cables, particularly in the process of stranding multiple wires together to create a single, more robust conductor. Factories that specialize in the production of bow stranding machines play a critical role within the electrical engineering sector, as they provide the equipment necessary for efficient and high-qualit

These factories employ advanced engineering and manufacturing techniques to create machines that can handle various types of wire materials, including copper, aluminum, and other alloys. The machines are designed to enhance the stranding process, where individual wires are twisted together in a helical or spiral configuration. This process not only increases the flexibility and durability of the wire but also improves its electrical conductivity and reduces the risk of wire breakage during installation or use.

In a bow stranding machine factory, several critical processes take place. First, raw materials are sourced and prepared, ensuring that they meet the stringent quality standards required for electrical applications. Next, precision engineering is applied to fabricate the essential components of the bow stranding machines, including the stranding heads, pay-off systems, and take-up units. These components must be crafted with high precision to ensure that the machines operate smoothly and efficiently.

Moreover, bow stranding machine factories often incorporate automation and advanced control systems, allowing for greater consistency and accuracy during the manufacturing process. This not only reduces production costs but also minimizes the potential for human error, resulting in higher-quality end products. Additionally, many factories focus on implementing environmentally friendly practices in their operations, such as recycling materials and minimizing waste, which is increasingly important in today’s manufacturing landscape.

Quality control is another vital aspect of bow stranding machine factories. Rigorous testing and inspection procedures are carried out at various stages of production to ensure that each machine meets the necessary performance and safety standards. This commitment to quality not only benefits the manufacturers but also provides confidence to customers who rely on these machines for their own wire production needs.

In summary, bow stranding machine factories are crucial to the electrical engineering industry, providing the necessary technology and equipment to produce high-quality wire and cable products. With advancements in technology and a focus on efficiency and sustainability, these factories are poised to continue playing a significant role in the evolution of wire manufacturing for years to come. Understanding their operations and contributions can provide valuable insights for professionals in the industry seeking to enhance their own manufacturing processes.

TAG:

Previous Page:

Recommend News

HEXING CABLE MACHINERY

TEL: +86-317-3601666, +86-317-3236119

FAX: +86-317-3618408

E-MAIL: china@hbhxdg.cn

E-MAIL: hbhxdg@gmail.com

WEB: http://www.hbhxdg.cn

ADD: Baoantun Industrial Zone, Hejian City, Hebei Province